Installation design

Floating installation design

The floatover analysis cover the loadout, transportation, standby, docking, mating and undocking phases

- KL10-2 CEPC Floatover Installation Analysis

- CFD6-4 CEPB Floatover Installation Design

- BZ26-6 CEPA Floatover Installation Design

- JZ23-2 CEPA CEPB Floatover Optional Installation Design

- HuiZhou26-6 DPP Topside Floatover Installation Design

- EP20-4 DPP Topside Floatover Installation Design & Support

- LMU Design and Analysis for DF 13-2 CEPB Floatover Installation Project

- JZ9-3 CEPD Topsides Floatover Installation Engineering

- QHD32-6 CEPJ Topsides Floatover Installation Engineering

- Dockwise/BNCPP-B Topsides Mooring & Mating Analysis

- KL3-2 Topsides Floatover Installation Engineering

- BZ35-2 Topsides Floatover Installation Engineering

Installation desigh of submarine pipelines

- Lake Water Abstraction (LWA) Offshore Pipeline Installation

- Weizhou10-3 offshore pipeline installation analysis

- Weizhou 5-3 Pipelay Installation Design

- Pipeline installation design for DF1-1 WHPF TO DF13-2

- SPL Pipelay Installation

- WeiZhou5-7 Pipelay Installation Design

- Pipeline Installation Design for North of Wei Zhou Project

- LS25-1 PLET and Gravity Anchor and Pipeline Installation Design

- 4" Gas pipeline repair engineering for LD5-2N PRP 2 SZ36-1CEPN

- Pipeline Installation Design for Pipeline ENPING10-2 to 15-1&HYSY118

- Pipeline Installation Design for Damaged pipeline-LF13-2 -LF14-4

- HK OLNG Project ZYH101 Pipelaying Engineering

- HK OLNG Project HYSY202 Pipelaying Engineering

- Pipeline Installation Design -(LF13-2 LF14-4 LF15-1)

- LingShui17-2 Project 6 inch SCR and PLET Installation Design

- BZ34-1 CEPA 3KM Old Pipeline Recovery Analysis & New Pipelaying Analysis

- Pipeline Installation Design for PL19-3 Oilfeild 4 Area Adjustment

- Pipeline Installation Design for LF13-1/LF13-2 Field Pipeline Replacement

- Subsea Pipeline Installation Design from LF13-1 DPP to LF13-2 DPP

- LH16-2 PLET Installation Analyses

- PL19-3 Block#4 Two Subsea Pipelines Installation Analyses

- BZ19-6 Two Subsea Pipelines Installation Analyses

- Six Subsea Pipeline Installation Analyses for LD21-2 and LD16-3

- Pipeline Design for BOZHONG Area Development

- Subsea Pipeline Installation for BZ34-9 Field Development

- Pipeline Installation Feasibility Analysis with HYSY202 for Dangote Phase II-Nigerian Project

- Saudi CRPO3648 Project Pipe Laying Analysis

- MaMu YuShan Pipeline Installation Design

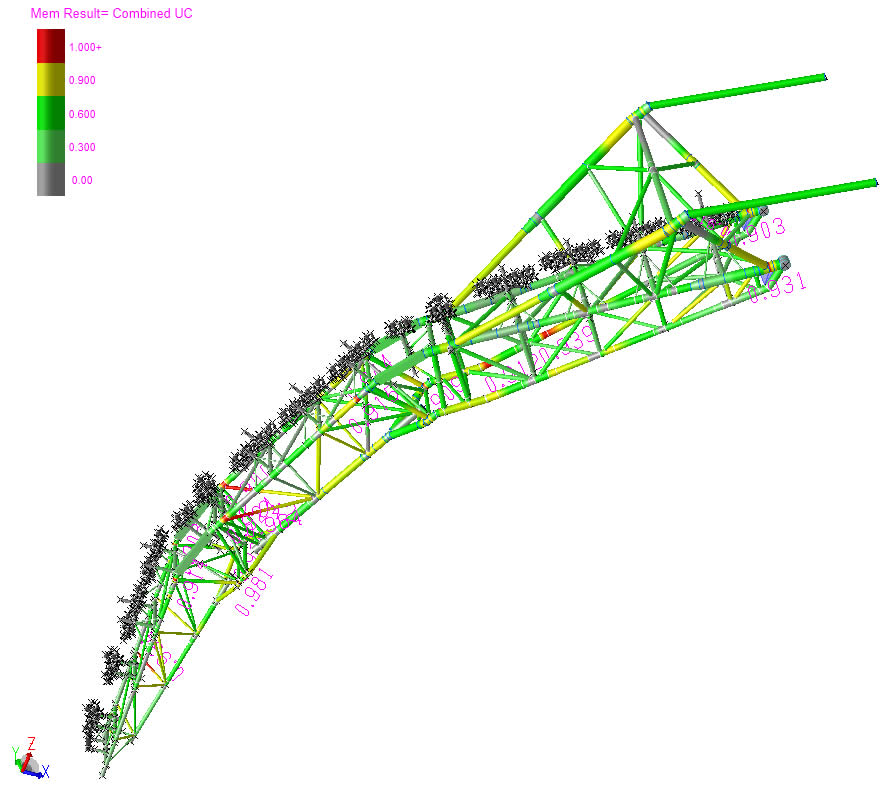

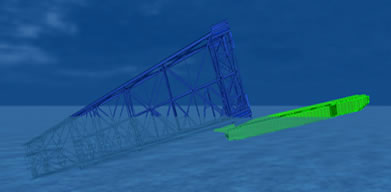

- Stinger redesign of Lanjiang for Brunei project

- Design of the Mini Stinger for HYSY202

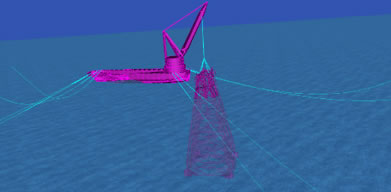

- Zawtika Phase 1B-Mooring Analysis for Pipelaying

Pipe laying simulation analysis

Strucural Design of Custody Rack

Installation design of conduit rack

- Weizhou10-3 Jacket and Topside Installation Deisng

- NB27-5 WHPA Jacket Installation Design

- PTTEP-HILONG Re-use Jacket Install Design incl. Wet-tow Analysis

- Qingzhou5-7 Jacket Installation Design

- XiHu BOP Jacket Installation Design

- PanYu10-1 WHPA Jacket Installation Design

- HuiZhou26-6 DPP Jacket Installation Design

- LH11-1 DPP Jacket (No.7) Installation Design

- LuFeng8-1 DPP Jacket Installation Design

- NB19-6 WHPA Jacket Installation Design

- LF15-1 DPP Jacket Installation Design Independ Verification

- Modules Lifting Analysis and Ballasting Analysis for Penguin FPSO Project FPSO

- WuShi17-2 Self Install Platform T&I Study

- Jacket and Topside Installation Design for Sheyang OWF

- HYSY 115 FPSO Production Separator Installation Design

- LF14-4 DPP Jacket Third Party Independent Verification and Review

- LD21-2 WHPA WHPB JACKETS INSTALLATION DESIGN

- Wet Tow Analysis for DF 13-2 CEPB Jacket

- Barge Capacity verification for WC13-2 WHPB Jacket Launch with HYSY221

- WC9-2/9-3 Jacket Wet-Tow Analysis

- MDK WHP Jacket Two-Hooks Lift Upending MDK WHP

- ZAWTIKA Phase 1B WP4/WP5/WP6/WP7 Jacket Installation Design

- Brunei BSP Jacket and Topsides Installation Engineering

- PY34-1 CEP Jacket Installation Engineering

Block installation design

- EP10-2 Deck and EP15-1 Modules Installation Design

- LF15-1 DPP Topsides Installation Design

- Topside loadout and transport for Datang-shantou OWF

- Motion Analysis of HYSY268 with 150T Crawler Crane

- LH16-2 LPG Storage Tank Transportation Engineering

- Towing Stability and Seafastening Design for Bridge Connecting CFD11-6 CEPI and CFD11-6 WHPD

- ZhongYouHai82 Platform Tow Stability Evaluation and Support Strength Check

- Module Lifting Analyses and Ballasting Analysis for LH16-2 FPSO Project

- ZJNYJNPD Wind Power Station Topside Installation Design

- Fatigue Analysis for NFA WHP-3 topside Transportation of Qatar Project

- FPSO P70 Modules Transportation Design

- KQT WHPA & WHPB Topside, WHPA (LQ) Installation Design

- E&P PRESALT FPSOs Modules Lifting Design PRESALT FPSOs

- Zawtika Phase 1B-Mooring Analysis for Topsides Installation

- HY1-1CEP, HY1-1/2-2WHPA Topside Installation Design

Subsea Structure Installation Design

- DMA Design for Ruya

- PLEM Lowering Analysis using CFD for DANGOTE Project

- Spool Installation and Mooring Analysis for Dangote Project in Nigeria

- Dangote Anchor Pile and PLEM Pile and Pile Flower Associated Analysis

- Brunei HengYi Project Floating and Submarine Hoses Engineering

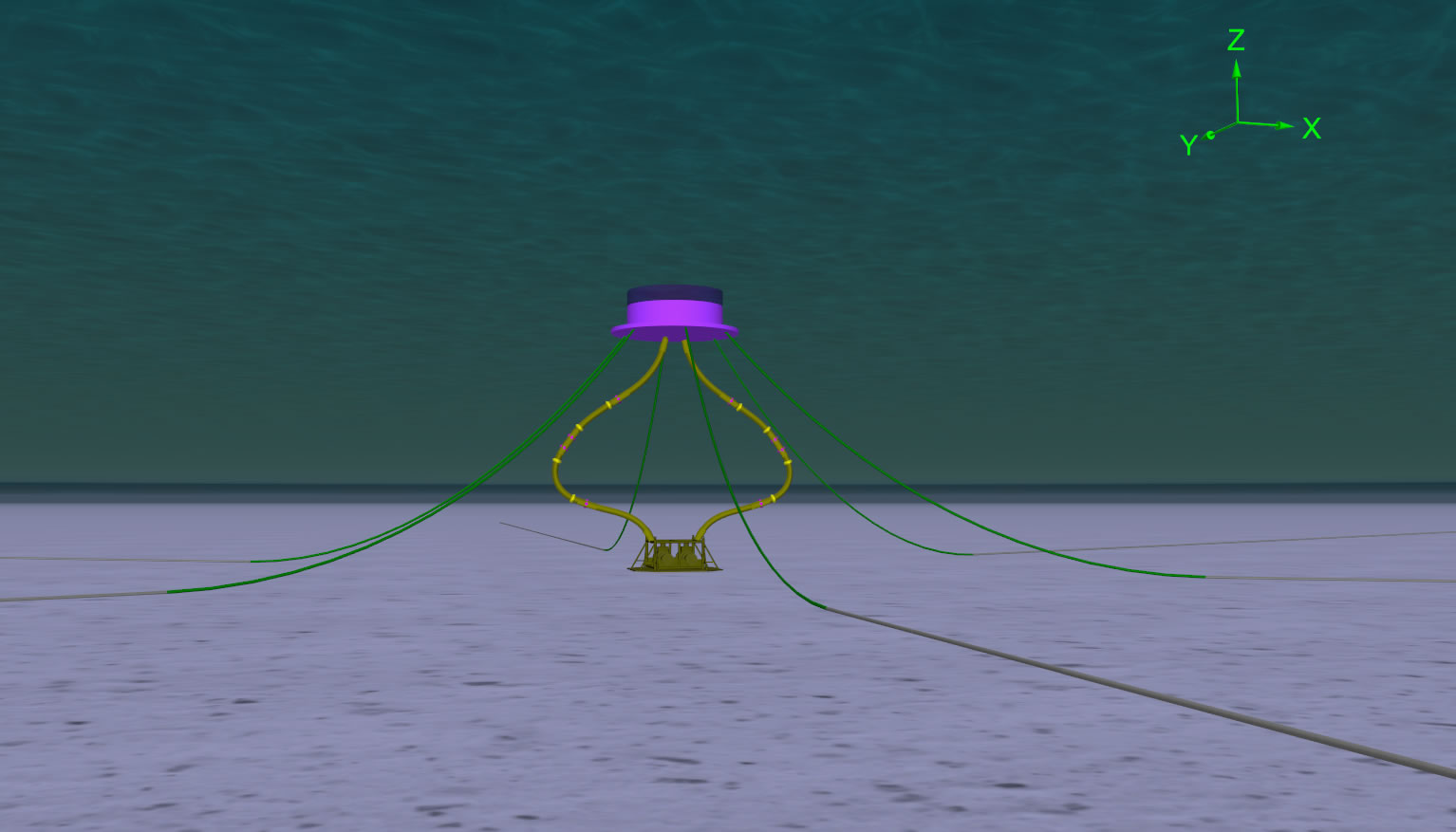

- Deadman Anchor Design For LS17-2 Project

- CDSR WuShi23-5 SPM Project Floating Hoses Analyses

Platform Upgrade, Modification and Assessment

- ZYH62 Platform update

- Diamond Offshore/Ocean Rover Wind Deck Drafting

- Ocean Valiant - Solan Ampelmann Gangway Extension

- Diamond Offshore/Ocean Quest Helideck Design

- Diamond Offshore/Ocean Valiant Helideck Design

Heary Marine Transportation

- HMT Engineering for Rigmar Jack-up

- HMT Engineering for the Dry Tow of AMAZONE Jack-Up,from Tuzla of Turkey to Sabetta of Russia.

- HMT Dry Tow Seafastening Design Standardization and Study

- NanHaiBaHao Semi-Submersible Transportation Verification for HYSY278,from Shenzhen of China to Murmansk to Russia.

- COOEC AZ Q-Bid_Sponson Design of HYSY278 for HYSY981 Dry Tow